3D printer

1.3D printer new reseach or application

1-1 Process support breakthrough:

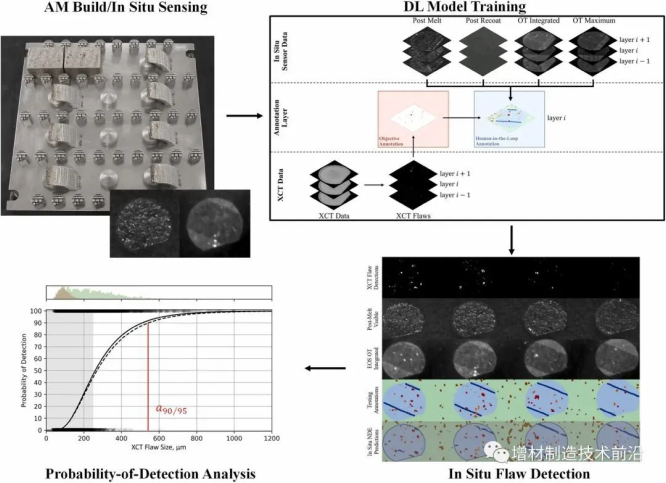

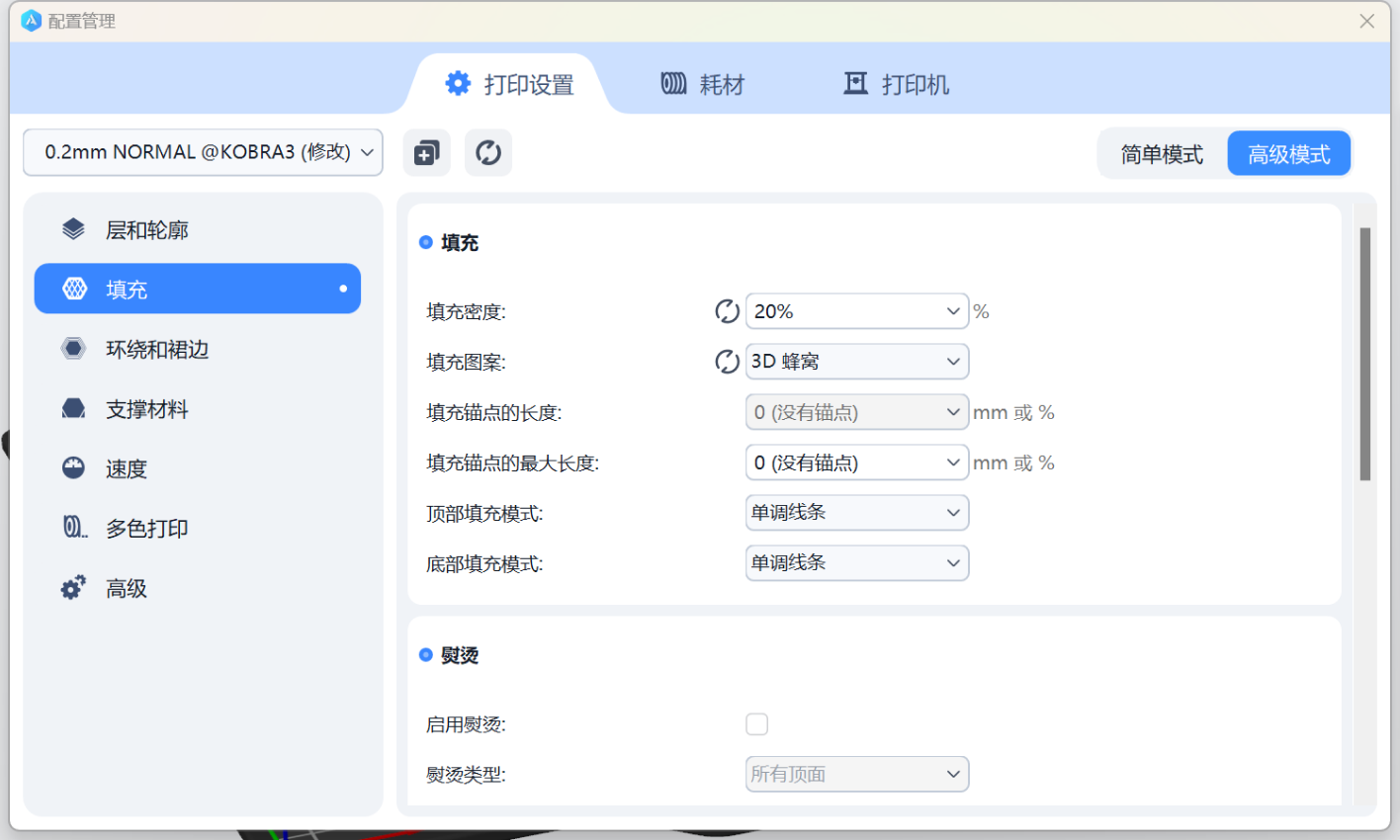

3D printing process non-destructive evaluation 90% detection rate

The first study on 3D printing technology published in Science in 2023

was published on January 5. A research team led by Tao Sun, associate

professor of Materials Science and Engineering at the University of

Virginia, has made the discovery that a method to detect keyhole

generation by integrating experimental data, multi-physics simulation,

and machine learning is able to capture the unique thermal features

associated with keyhole generation with sub-milliseconal time resolution

and a 100% prediction rate.

Researchers at Oak Ridge National Laboratory have developed a way to

combine post-inspection data from printed parts with information

collected by sensors during the printing process, and the combined data

teaches machine learning algorithms to identify defects in products.

This new method achieves a 90% detection rate, which is consistent with

the defect detection probability of traditional evaluation methods, thus

saving time and reducing costs.

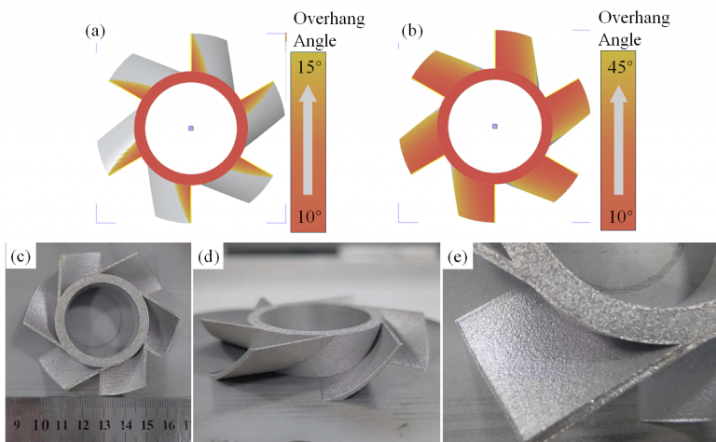

1-2 New technology:

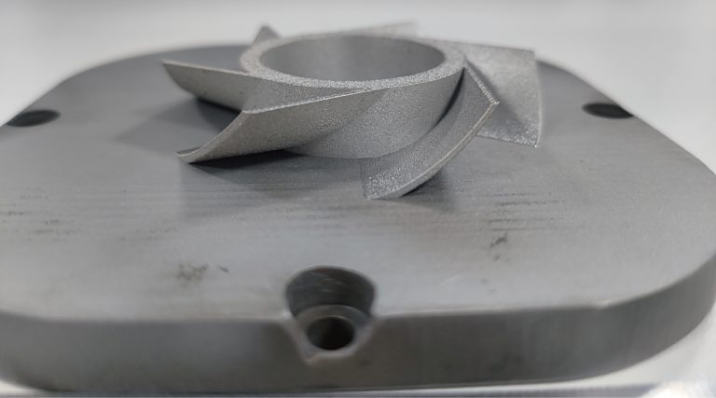

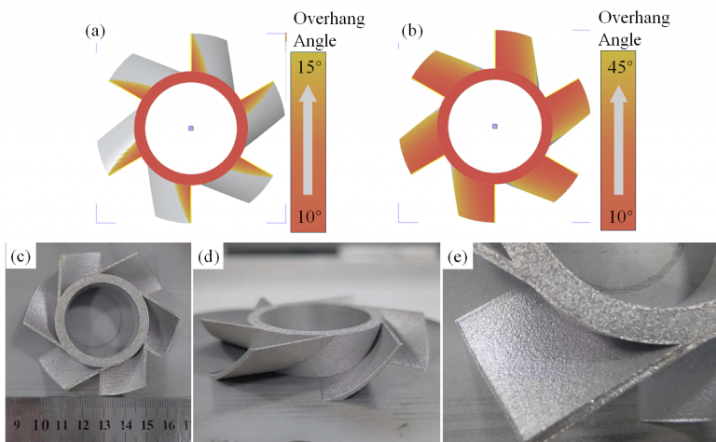

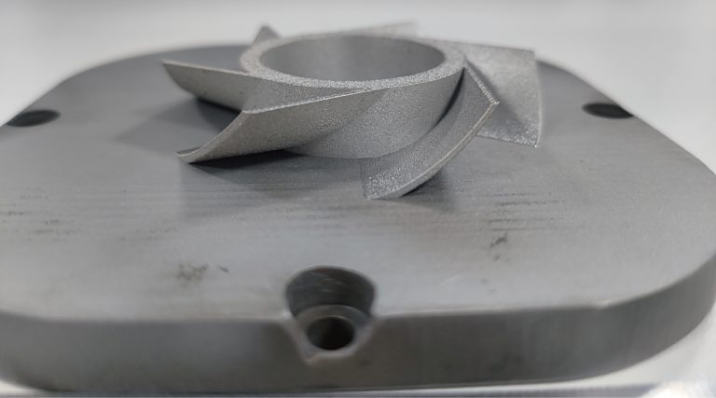

Unsupported metal 3D printing

In recent years, through years of continuous research and development

and repeated trials, Jinshi 3D core technology team, under the

leadership of chief scientist Professor Yang Yongqiang, has made

important breakthroughs in the field of unsupported metal 3D printing:

Breaking the 45° limit and developing a universally applicable

unsupported low Angle forming method to achieve the effective forming of

industrial parts in large overhang areas, has successfully printed

unsupported metal impellers and other samples with the lowest Angle of

15°, providing application solutions for many industries.

In February 2024, Professor Yang Yongqiang and Professor Wang Di of

South China University of Technology, the core scientific research team

of Jinshi 3D, jointly published an invited paper entitled "Research

on the Method and process of Laser Selective Melting Forming of

Low-angle Unsupported Structures" in the journal of China Laser.

The forming mechanism, the surface quality of the sample and the

applicability of the forming method of unsupported metal printing were

investigated, and the actual industrial parts were used for printing

verification.

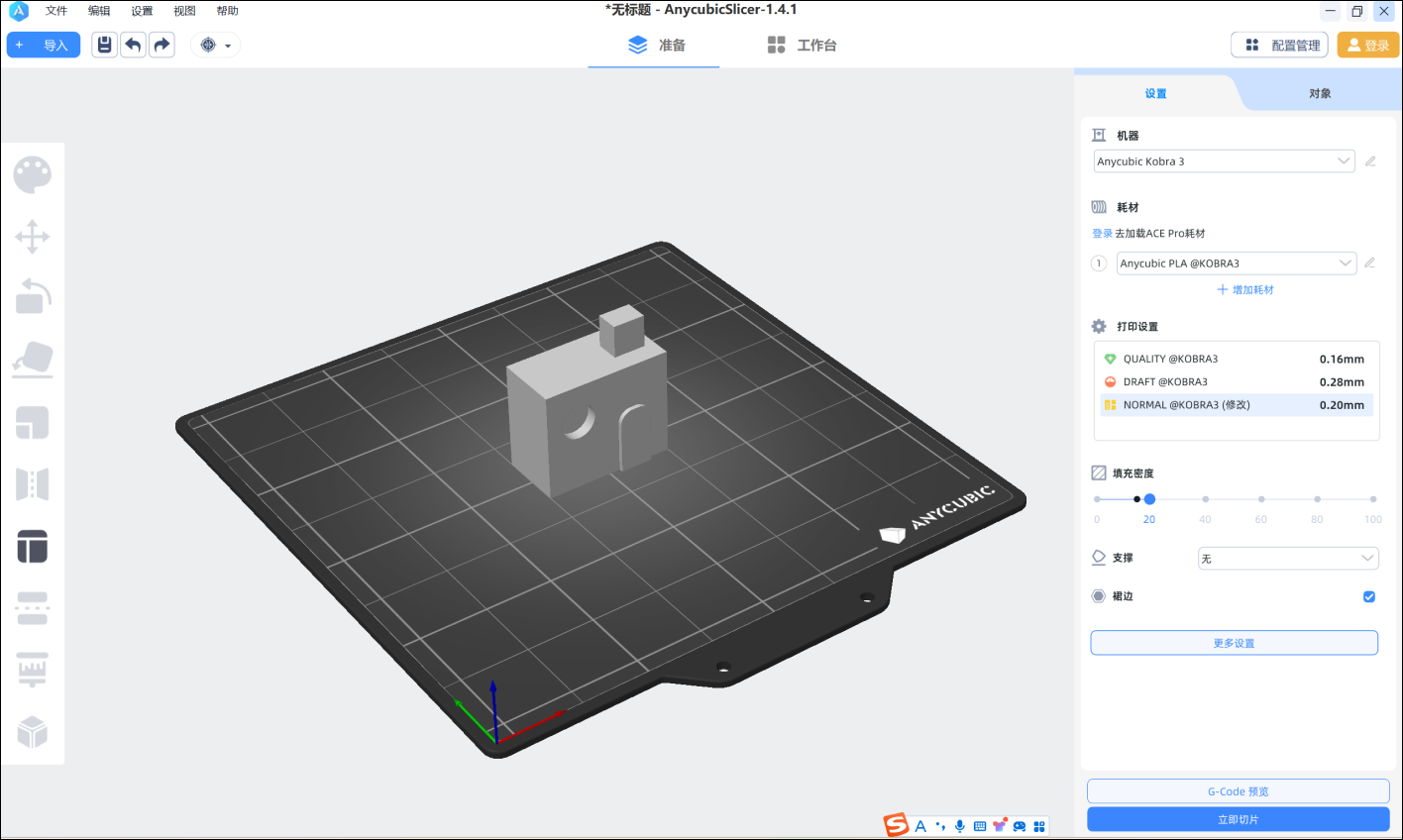

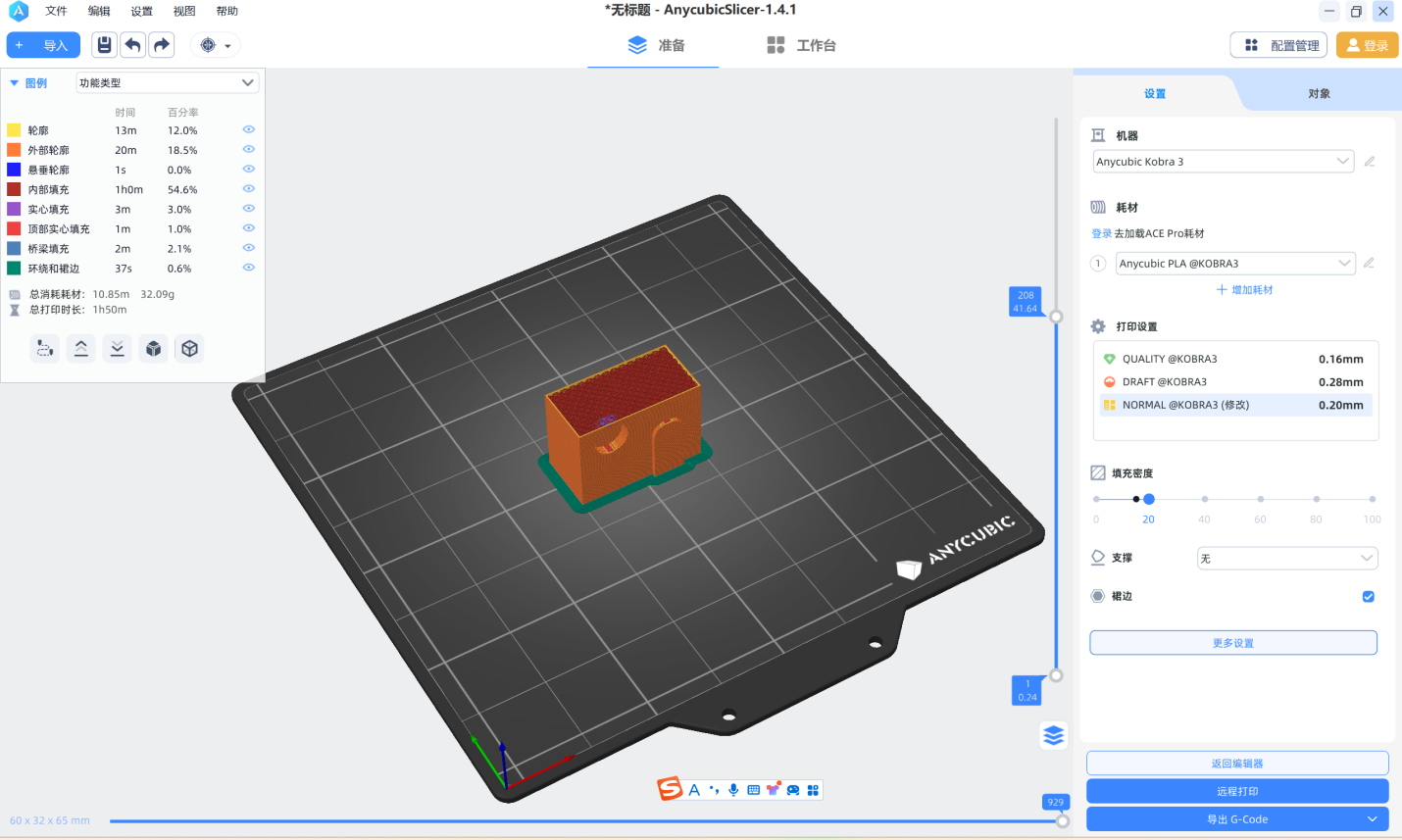

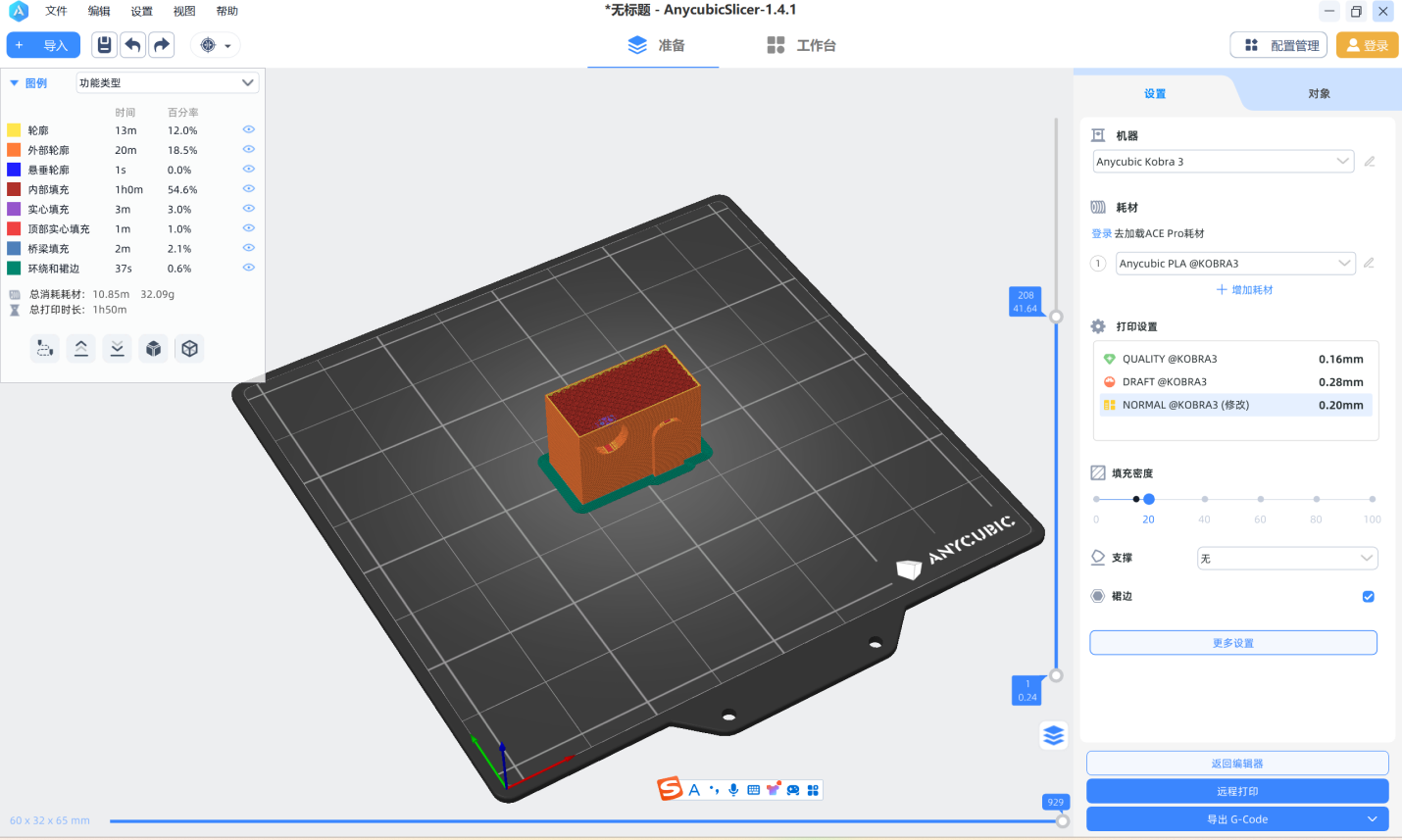

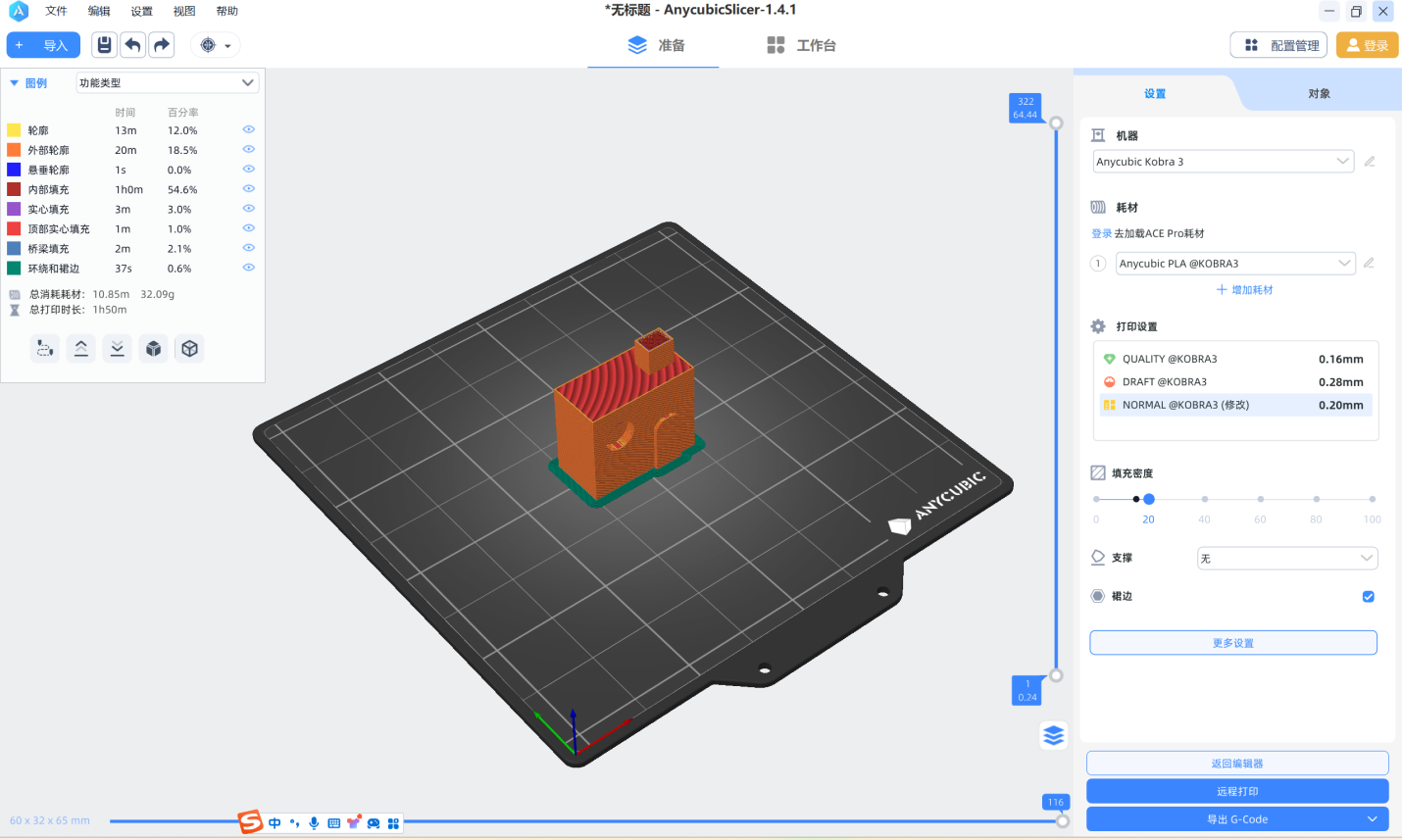

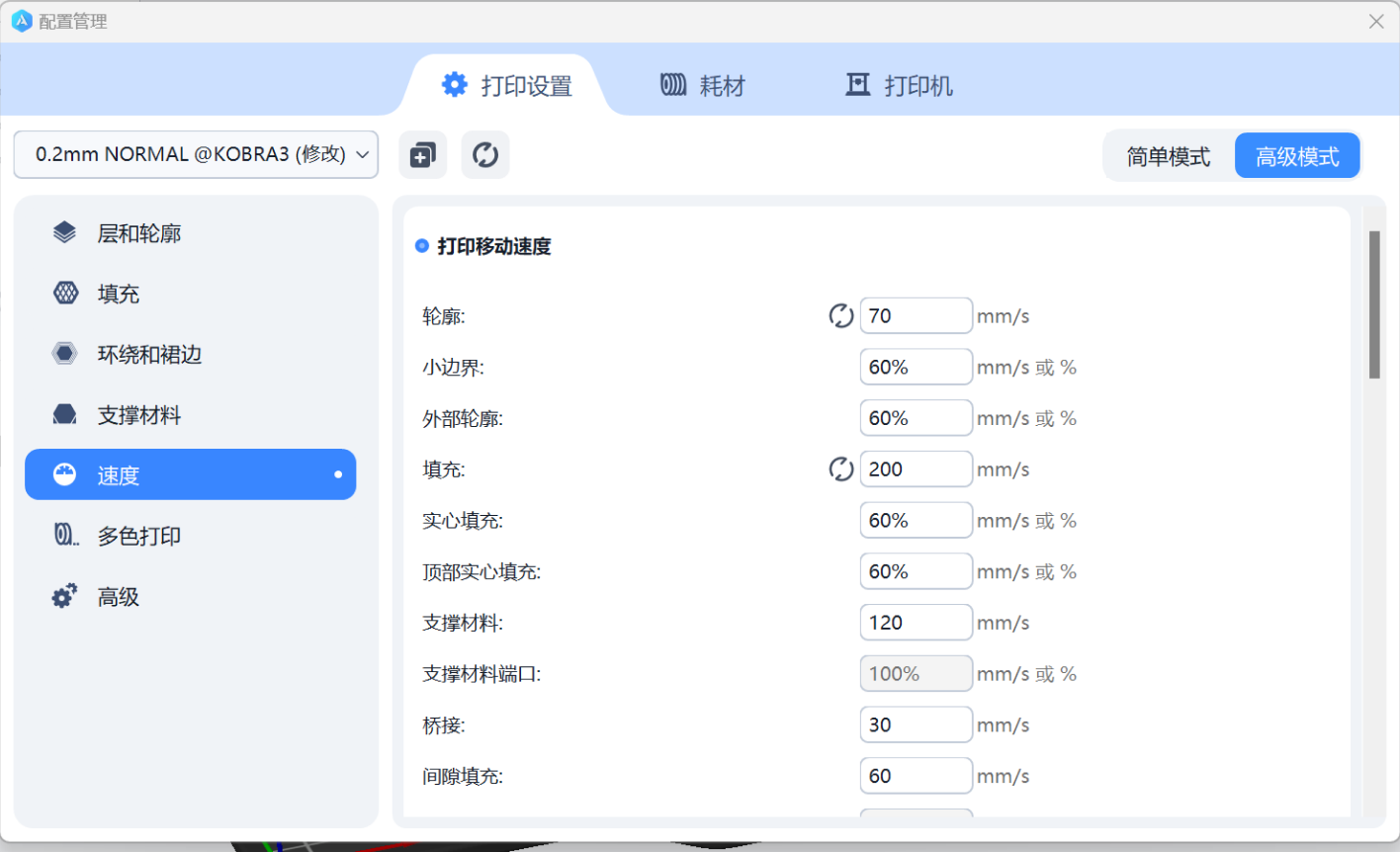

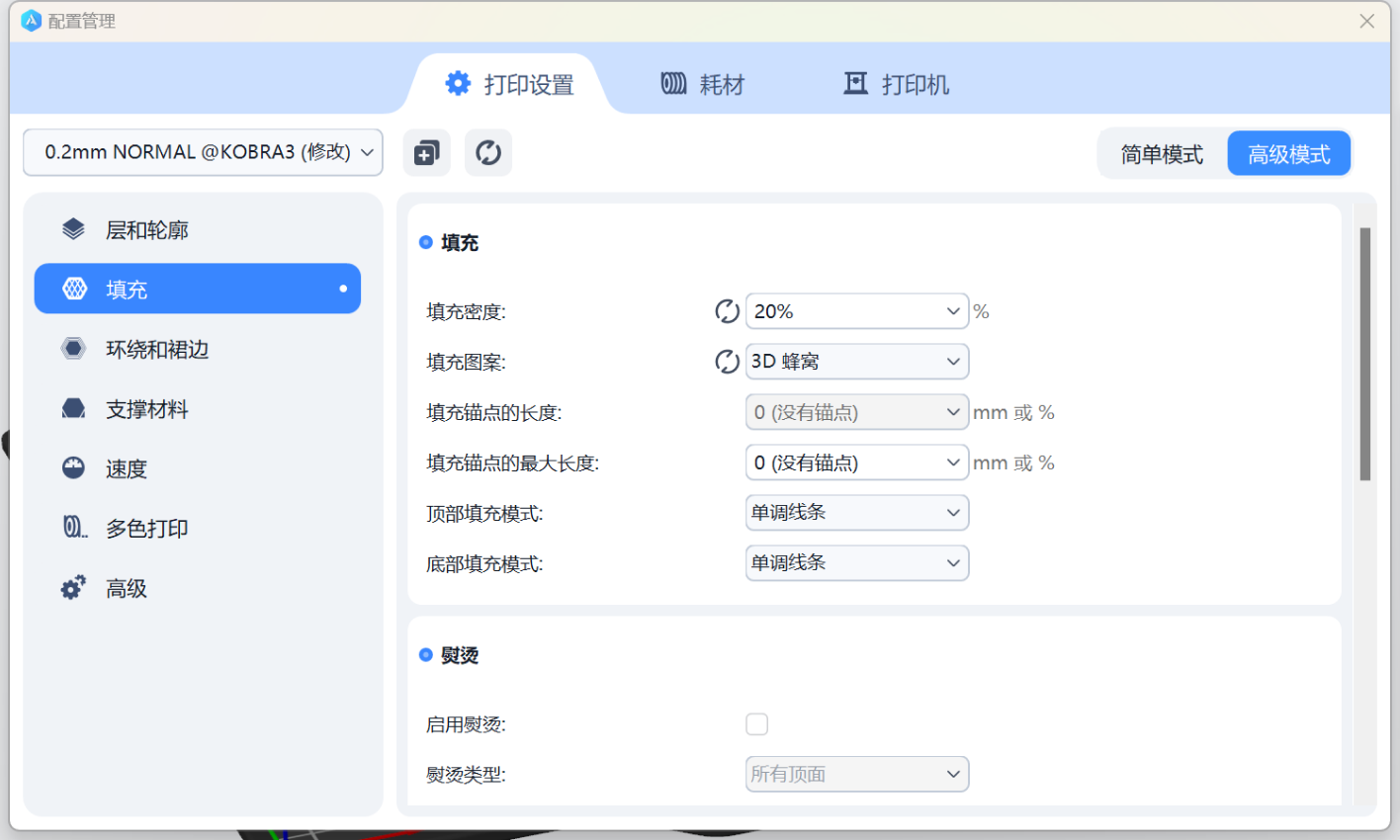

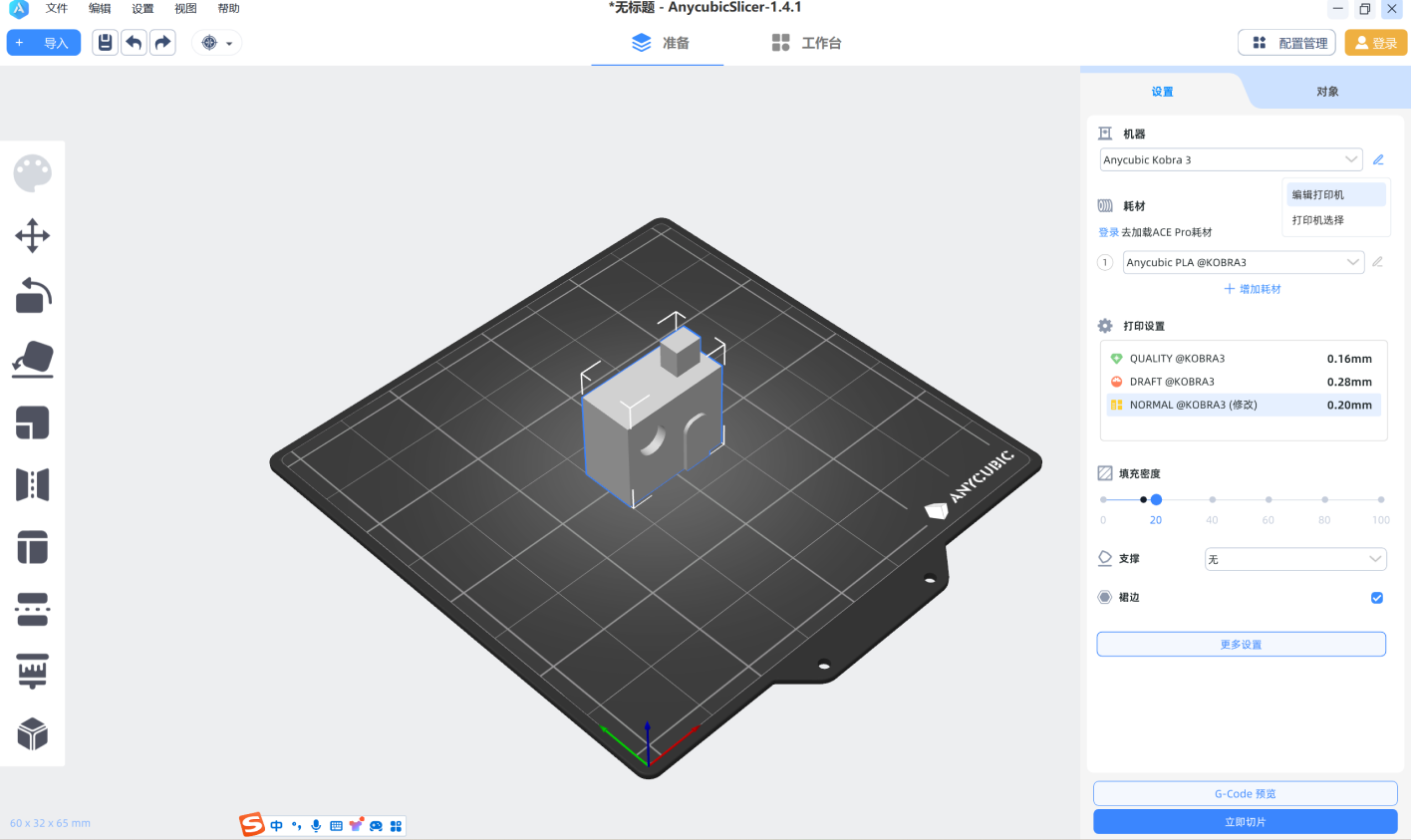

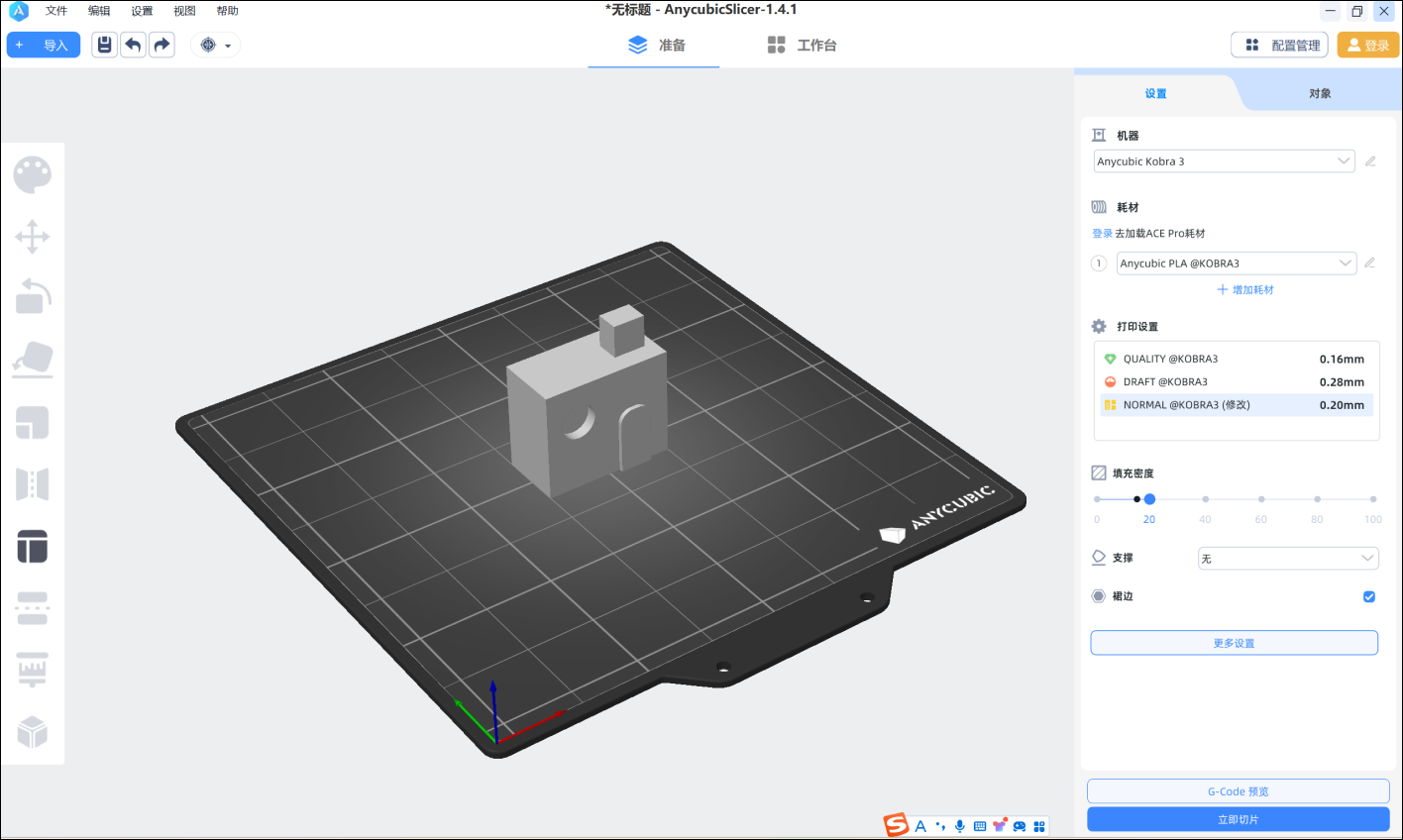

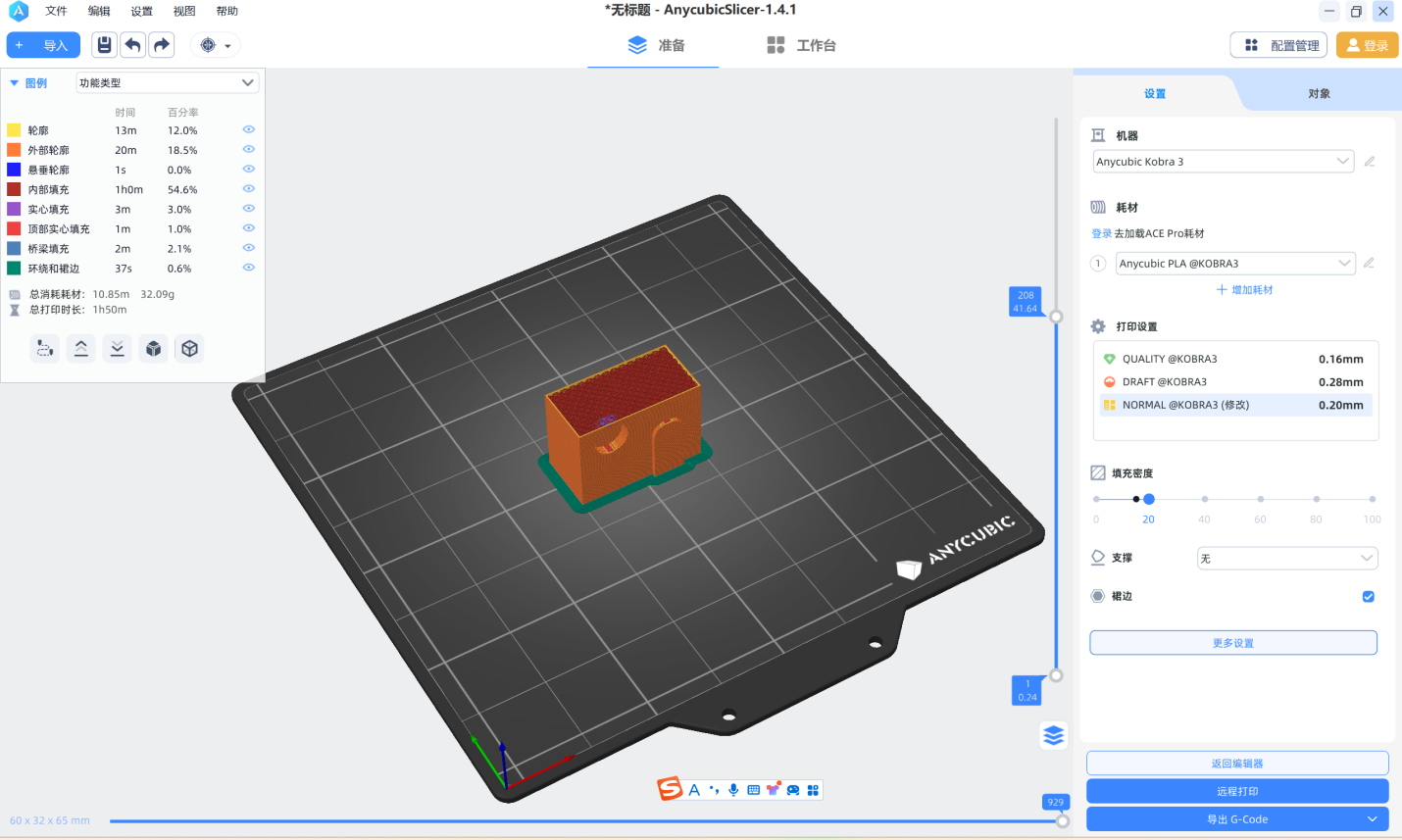

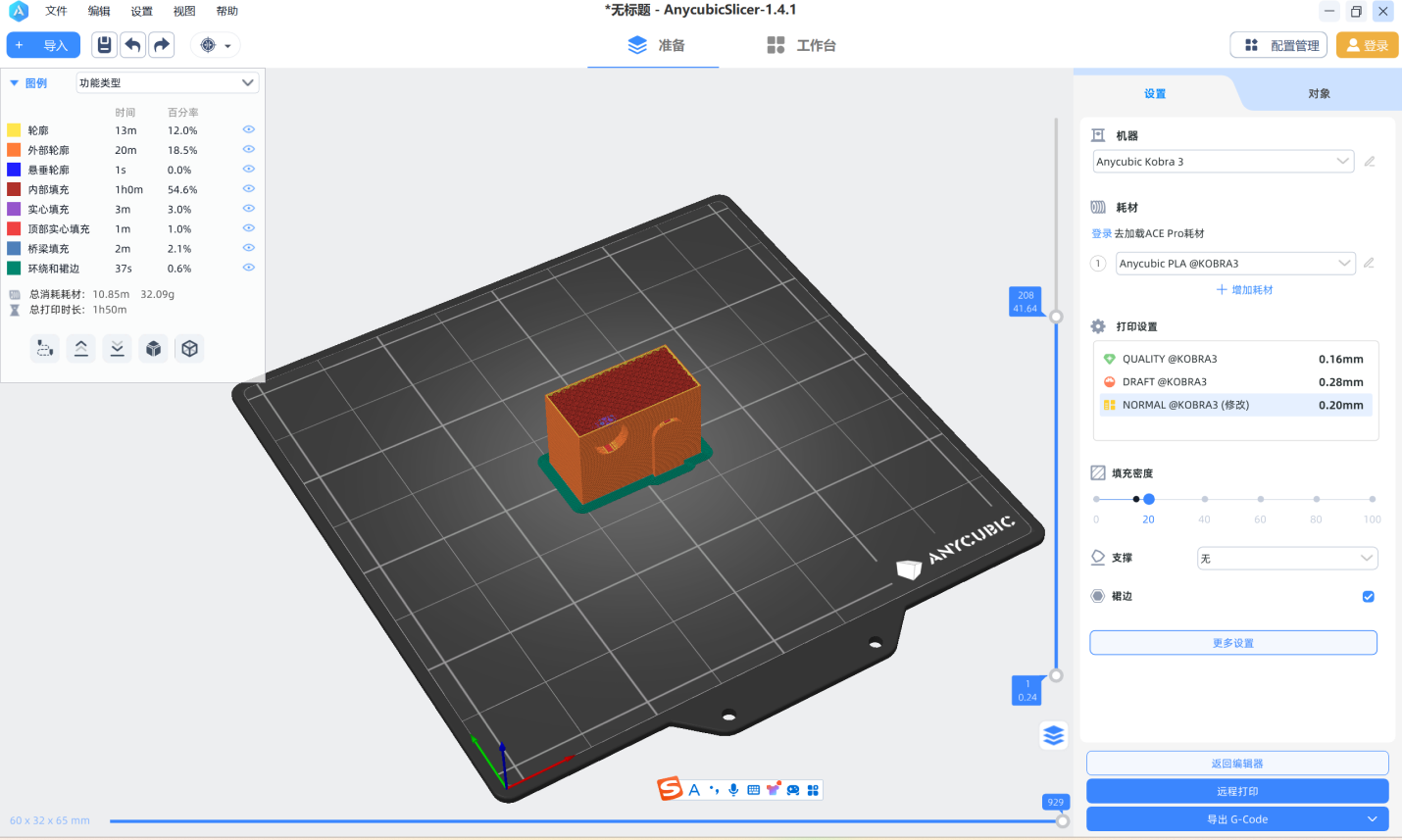

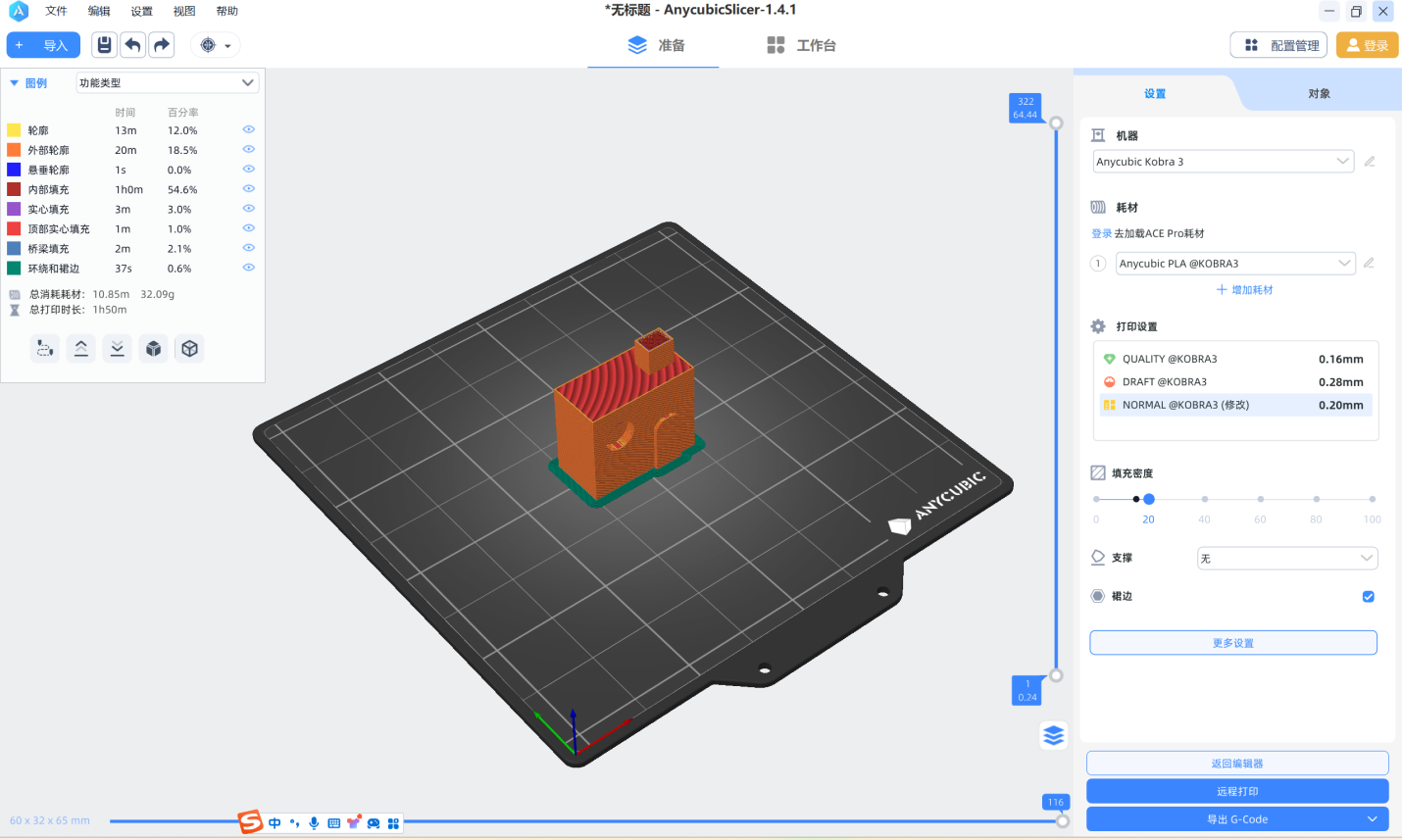

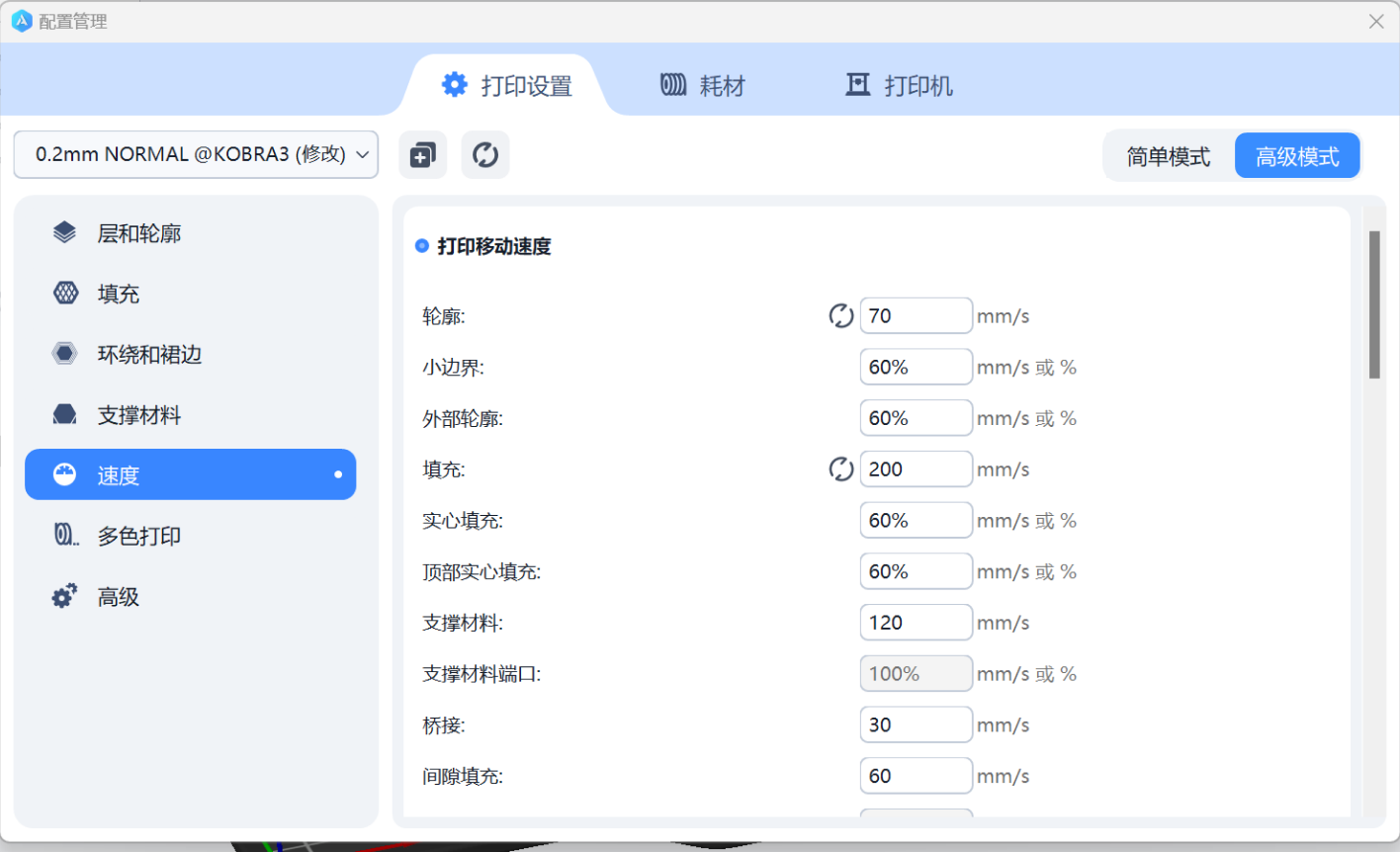

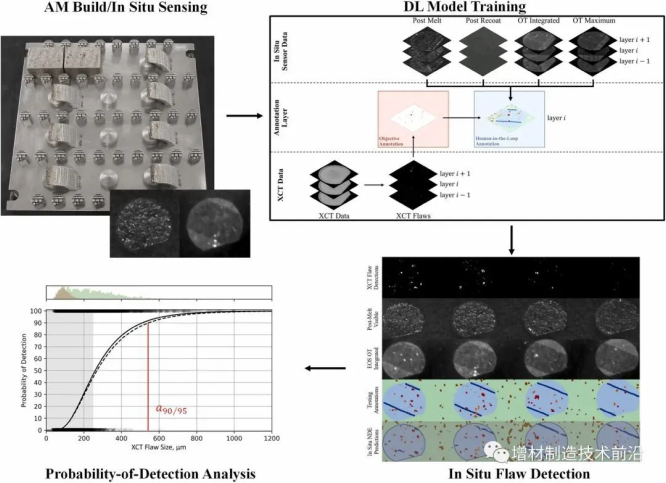

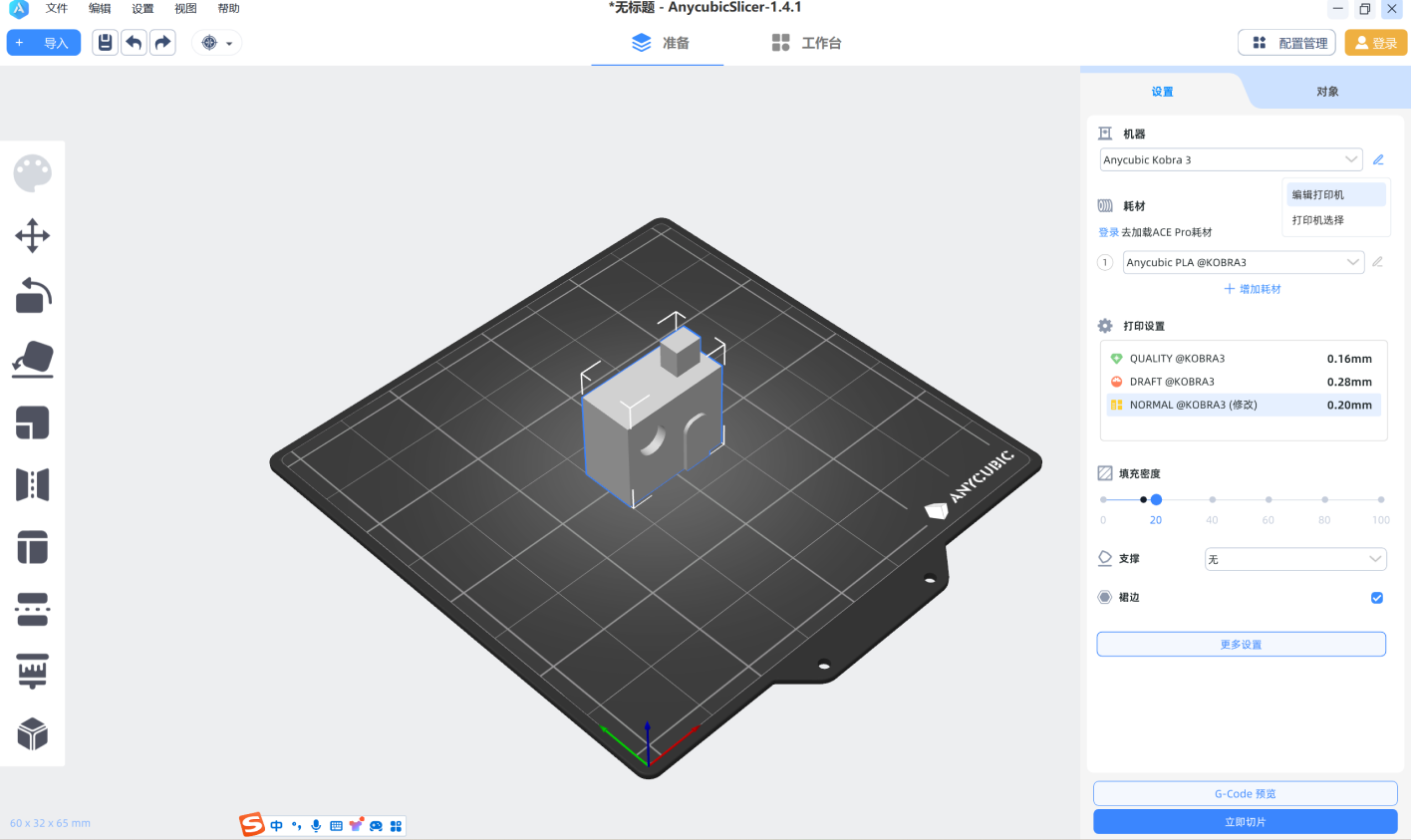

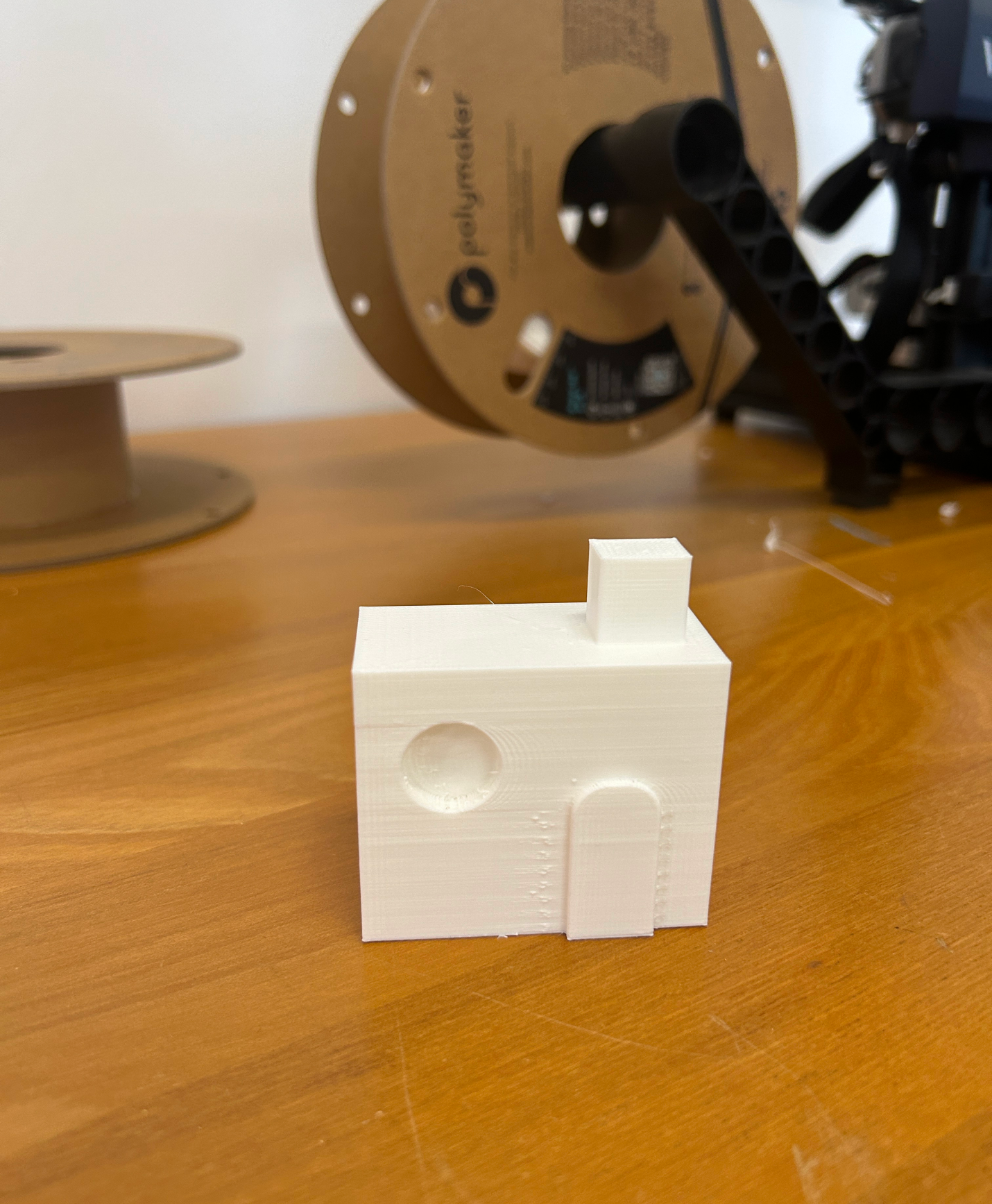

2.Use slice software to setting parameter

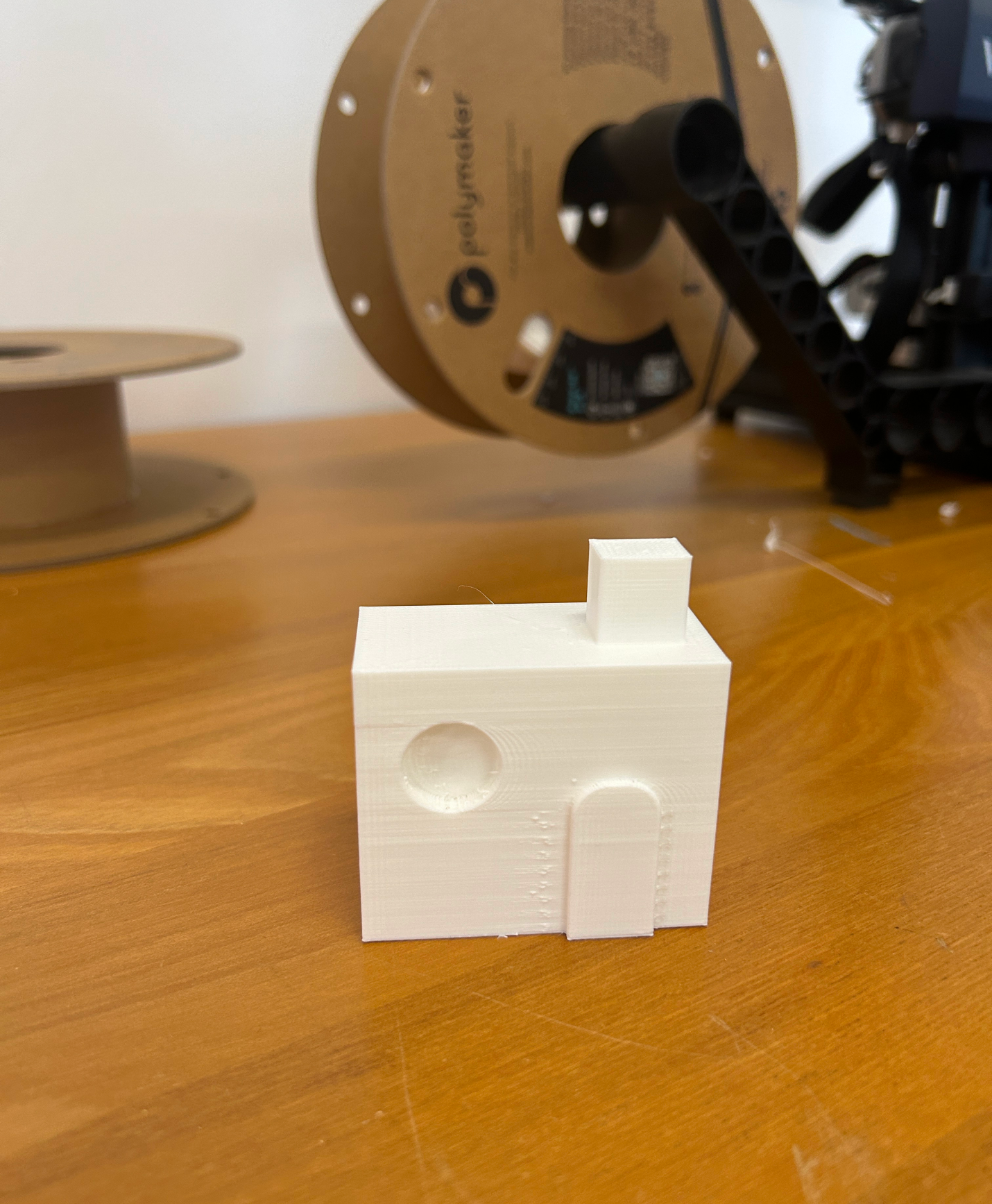

3.Use 3D printer to manufacture it

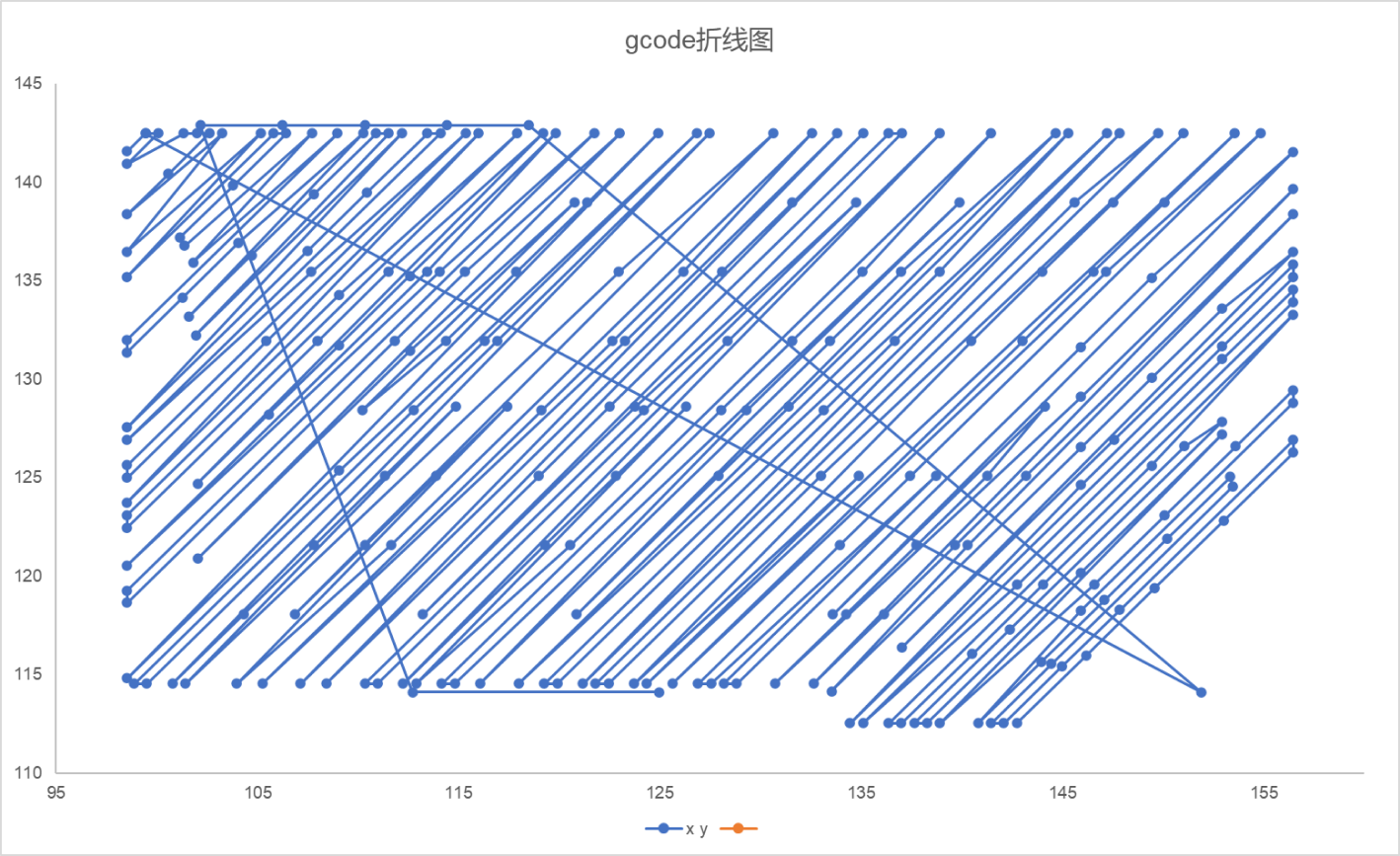

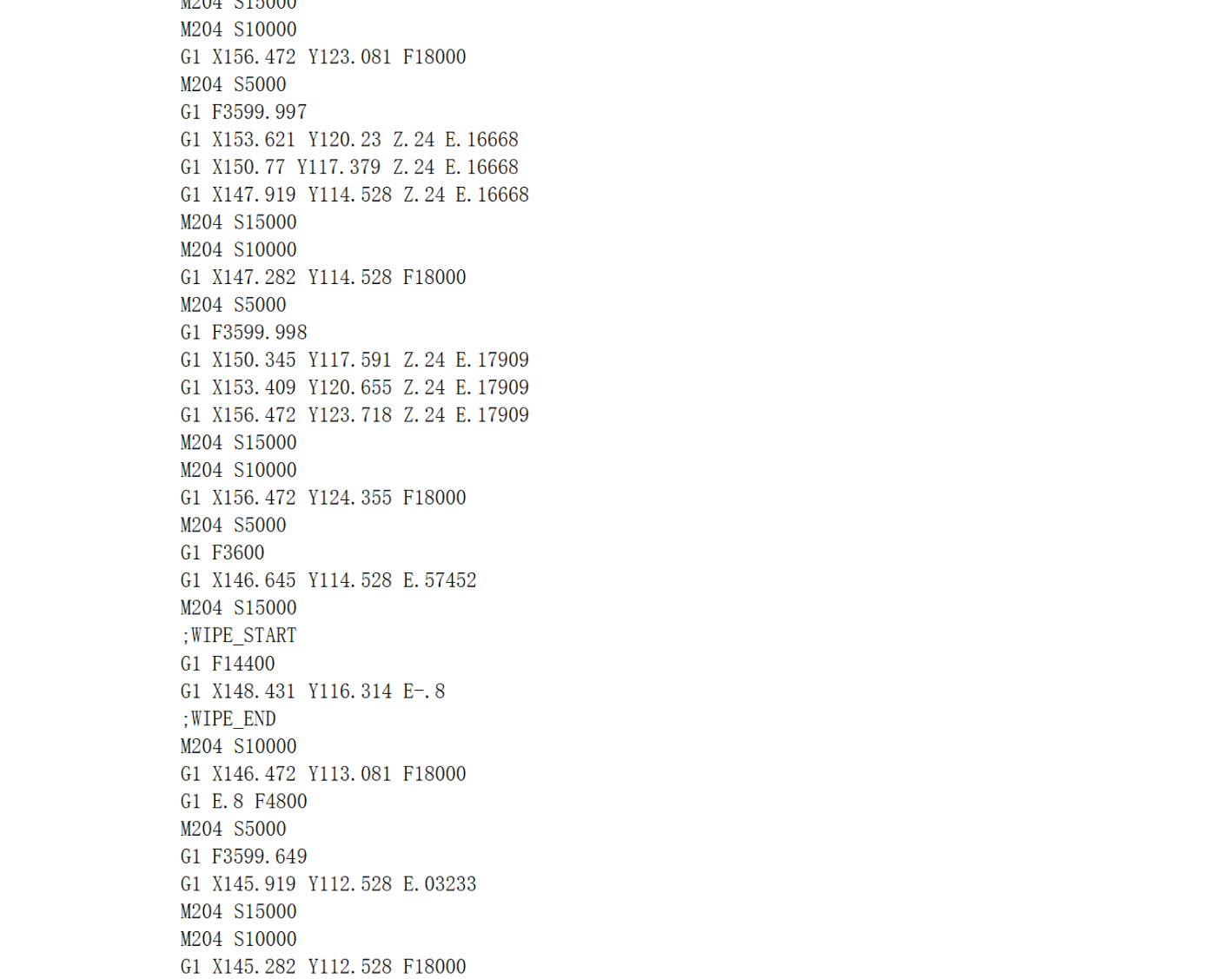

Select gcode

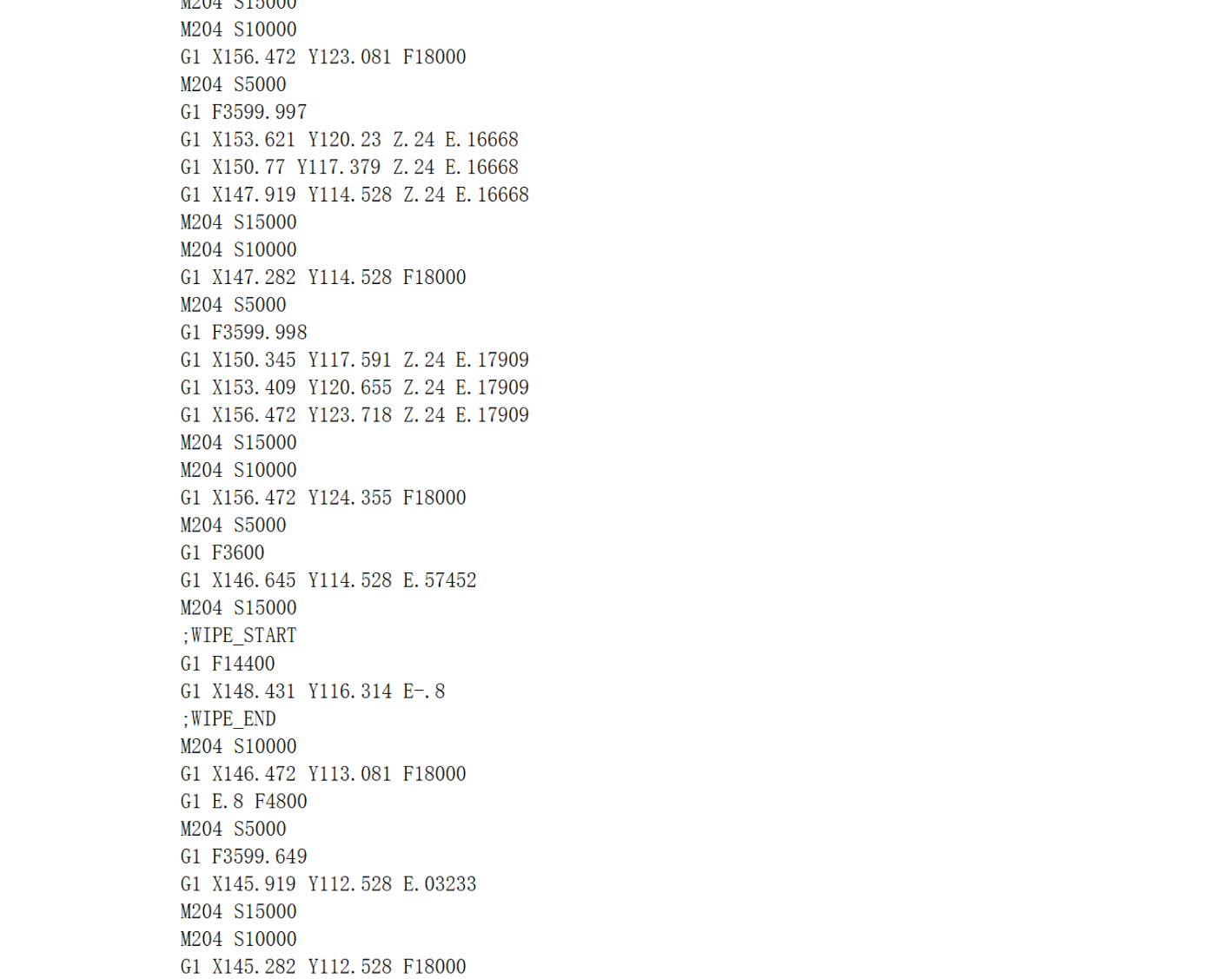

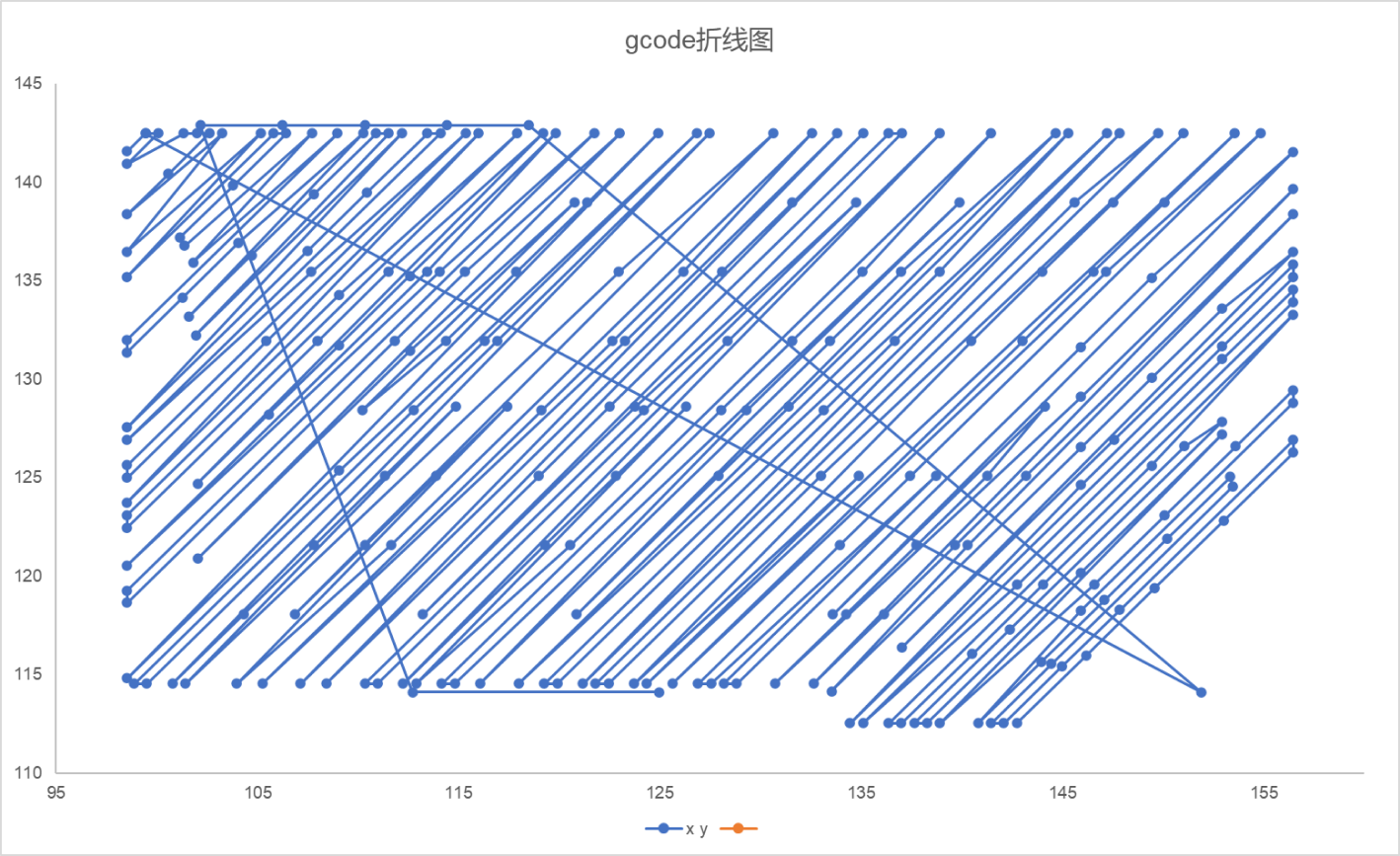

Draw gcode line chart

...

填充密度:20%

填充图案:3D蜂窝

裙边类型:内部和外部裙边

速度:轮廓:70mm/s 填充:200mm/s